“Corn, soybean ground, sandy ground, gumbo – it’s an amazing tool.”

It’s that kind of tool — the kind a farmer recommends to his friends and neighbors — an implement of unmatched versatility that saves time, labor and fuel and, they say, “does a heckuva job.”

That’s what farmers tell other farmers about the Kelly Diamond Harrow. And they’ve proven it themselves where it counts — in the field.

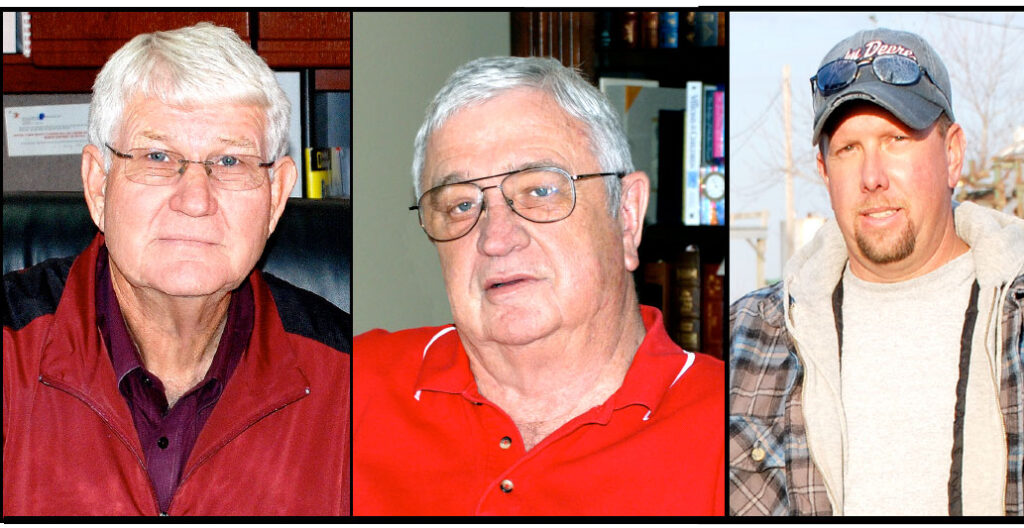

“Duane Gaither is a very good friend of mine and he told me I really needed a

Kelly,” says Ron Pigue who farms 5,000 acres of rice, corn and soybeans near Paragould, Ark.

“Duane’s a top farmer and he knows what he’s talking about, so I tried one and he was right — I did need a Kelly.”

The operation now has two Kelly Diamond Harrows and although Ron and his son,

David, initially thought they’d use their Kelly Diamond Harrows exclusively on rice growing in their demanding gumbo soils, they soon expanded to other applications.

“Corn, soybean ground, sandy loam, gumbo — it’s an amazing tool,” Ron says.

Manufactured by Kelly Engineering, the Kelly Diamond Harrows Gaither and Pigue run are 45-foot models. The hydraulically-folding units feature flexible disc gangs on an industrial chain and mounted to a diamond-shaped steel frame. The offset chains are drawn across the ground at an angle, filling in ruts, fluffing and scarifying residue and leaving a top-notch seedbed.

“We use it to get a roughed-up field back into shape and we use it as our final tool before planting,” Ron explains,

“In the spring, if you have a stale seedbed to loosen up, you can quickly work that top inch or so and get those early weeds. It gives you perfect, uniform residue cover for corn and beans, it fluffs up rice residue so you can get a good burn and you can pull it over bedded ground — it’s got a lot of uses.”

Duane Gaither was the first farmer in the country to give the Kelly Diamond Harrow a try and he now uses three of them on his 2,700 acres of continuous rice at Clover Bend Farms near Hoxie, Ark. Those three units, Gaither says, can cover 1,200 acres a day at a fuel cost that’s less than $2 per acre for three trips across a field — far less time and fuel to get his rice ground into shape than the field cultivator and land-plane operations it used to require.

“If it weren’t for the Kellys, I wouldn’t be following rice with rice,” says Gaither. “It’s a hard

crop to follow because of the thick root mass and the tremendous amount of straw you have to deal with. This is a very versatile tool, though. I got rid of all my discs and all my field cultivators and we don’t mess with the floats anymore.”

Gaither also appreciates the simplicity and reliability of the Kelly Diamond Harrow.

“As far as major problems, we just haven’t had any,” Gaither says. “The secret is to keep the chains tight. We check them every morning before we start. It’s pretty simple. There are four tensioners to check and you can do it in a matter of minutes. It’s a very simple, trouble-free machine.”

The Kelly Diamond Harrow’s blades are wear-guaranteed for 50,000 acres and the swivel bearings are guaranteed for 10,000 acres. Although he’s never had to replace a bearing, Gaither says it would be easily accomplished and the harrow comes with a spare to minimize down-time if he ever does.

Up the road near Reyno, Ark., Jim Cole likes the expanded planting window he gets with the Kelly Diamond Harrow. “In the early spring, you can pull the Kelly into a field when it’s pretty wet and you’ll dry out that ground in a day instead of in a week,” he says.

“You can pull the Kelly into a field when it’s pretty wet and you’ll dry out that ground in a day instead of in a week.” — Jim Cole, Reyno, Ark.

“Just working that top inch or two, you get a nice, smooth, level seedbed and it’ll really take care of whatever weeds that are there.” As useful as the Kelly Diamond Harrow is for seedbed. preparation, it’s just as handy as a primary tillage tool. Land that’s been rutted, or has been hipped-up, can quickly be put back into shape. On the Cole farm, there is a fair bit of soil type variation but the Kelly does a good job across the spectrum, even in the most challenging soils.

“This is a very versatile tool, though. I got rid of all my discs and my field cultiva- tors and we don’ t mess with floats any- more.” — Duane Gaither, Hoxie, Ark.

“This is the best gumbo tool ever made,” Cole says. “You can work any soil — tough as gumbo and light as sand — and it’s going to do a good job. You don’t get the slabs and clods in gumbo that you get with other tools and it saves us from having to run the land-plane.”

Results like that are hard to keep to yourself. Farmers looking for a better way of crop production are bound to notice, as Ron Pigue found out:

“My neighbor saw a field we’d just worked with the Kelly,” Ron recalls from the first season he used the innovative implement from Kelly Engineering. “He asked what we’d done — he knew it had been pretty rough before and he said it looked like it had been land- planed. I told him we went over it twice with the Kelly and that was it. Now he owns one, too.”